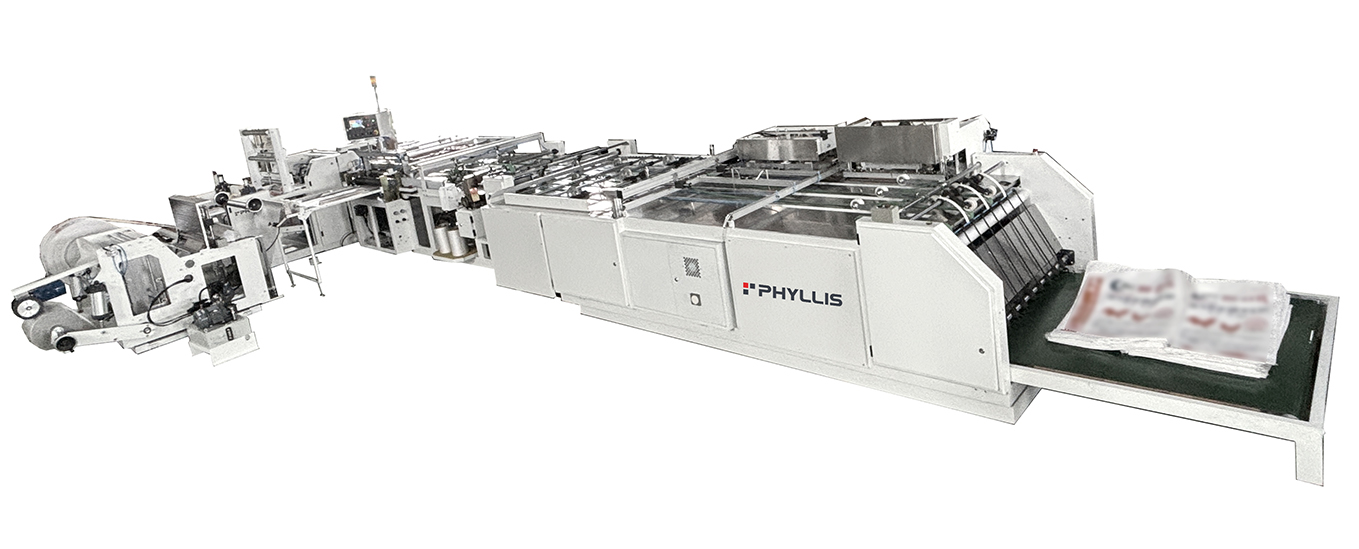

Conversion Line for PE liner insertion into PP woven sack with Top Hemming

Cutting edge technology of woven sack conversion line innovation has made automated manufacturing truly possible. A complete PE liner inserted PP woven sack with PP woven sack mouth hemming is to be manufactured by 1 machine in 1 single process automatically.

Manual sewing jobs on PP woven sack mouth has been replaced by machine; hence, labor and space occupied are reduced tremendously, which has made slim factory and lean manufacturing possible. Clean manufacturing process has been ensured because no human hand would be touching inside of PE inner liner. Massive reduction of sewing thread usage helps manufacturers to stay competitive in pricing.

- PE liner insertion into PP woven sack with top hemming speed up to 16 bags per minute

- Bag mouth can be folded or not folded

- Top hemming can be done with, or without PE inner liner

- Machine can work as standard cutting sewing machine

| Model Number | Konvatex I+H |

|---|---|

| Roll diameter (max.) | 1400 mm (PP woven fabric) |

| Application | 1. PE liner insertion into PP woven sack with top hemming 2. PP woven sack top hemming 3. PE liner insertion into PP woven sack 4. Standard PP woven sack cutting and sewing |

| 1. PE liner insertion into PP woven sack with top hemming | |

| Coated/uncoated cloth width (max.) | 450-750 mm |

| Sack length | 580-1200mm |

| Max. production capacity | 16 pcs/min |

| 2. PP woven sack top hemming *without PE liner insertion | |

| Coated/uncoated cloth width (max.) | 450-750 mm |

| Sack length | 580-1300mm |

| Max. production capacity | 17 pcs/min |

| 3. PE liner insertion into PP woven sack | |

| Coated/uncoated cloth width (max.) | 450-750 mm |

| Sack length | 580-1200mm |

| Max. production capacity | 34 pcs/min |

| 4. Standard PP woven sack cutting and sewing | |

| Coated/uncoated cloth width (max.) | 350-800 mm |

| Sack length | 560-1300mm |

| Max. production capacity | 45 pcs/min |

* Speed varies with different sizes of sacks, and quality of fabric and PE liner