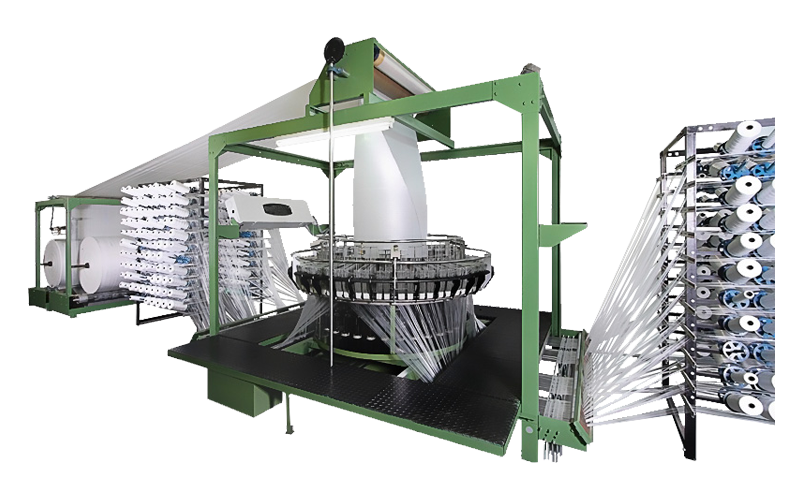

Métier à tisser circulaire (tissus robustes)

Cohérent, simple et flexible, les métiers à tisser sont faciles à utiliser et à entretenir, tout en produisant des tissus robustes de haute qualité adaptés aux FIBC, bâches et autres textiles spéciaux.

Specification

- Application for FIBC, Tarpaulin, and various applications

- Optional equipment of center slitting device, or both side slitting device

- Ultrasonic slitting device available upon request

- Warping roller system available upon request

- Patented design with enhanced life time of spare parts

- New circular rail design ensures stable shuttle movements

* depending on tape quality, fabric width and density

Technical Data

| Model Number | PH-6/150 | PH-8/215H |

|---|---|---|

| Application | FIBC, Tarpaulin | FIBC, Tarpaulin |

| Shuttle/machine | 6 pcs | 8 pcs |

| Max. Shuttle Speed | 90 rpm | 75 rpm |

| Weft insertion up to | 540 ppm | 600 ppm |

| Working width, tubular | 90 cm – 130 cm | 180 cm – 210 cm |

| Weft bobbin diameter (max.) | 100 mm | 110 mm |

| No. of warp creel (bobbins) | 1360 pcs | 2600 pcs |

| Warp/weft core inside diameter | Φ23 mm–Φ38 mm | Φ23 mm–Φ38 mm |

| Warp/weft length of core | 215 mm – 230 mm(L) | 215 mm – 230 mm(L) |

| Winding roll diameter (max.) | Φ1200mm | Φ1200mm |

| Main motor with inverter | 10 HP | 15 HP |

* depending on weaving construction, fabric, and quality of tapes